DLO-M2_ex density sensor for liquids

The DLO-M2_ex sensor for use in hazardous areas according to ATEX: II1G and IECEx: Zone 0 measures the density of liquids in a microelectromechanical system (MEMS system). Within the MEMS system, the liquid is directed to an omega-shaped microchannel, the so-called omega chip. This tiny silicon tube – it is hardly thicker than a hair – is set into oscillation for the measurement. The density of the medium can be derived from the natural frequency of this oscillation: the denser the medium, the lower the oscillation.

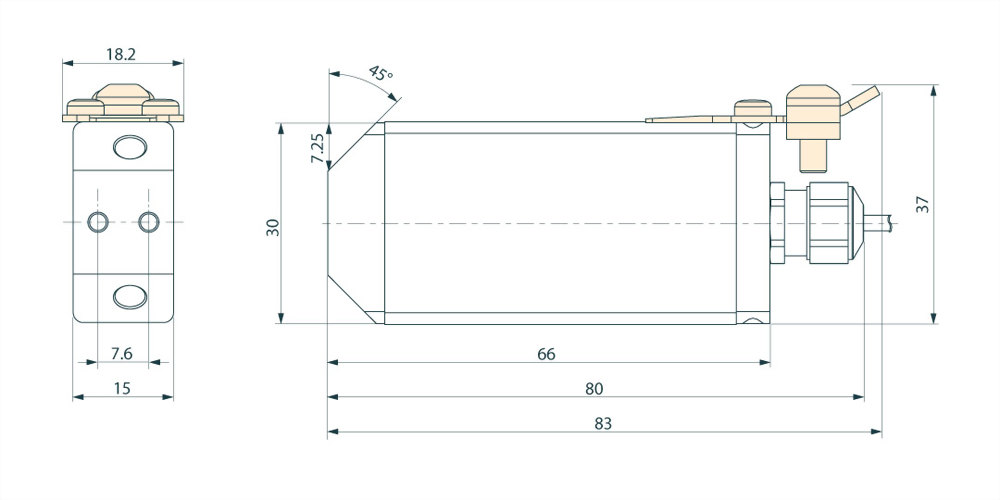

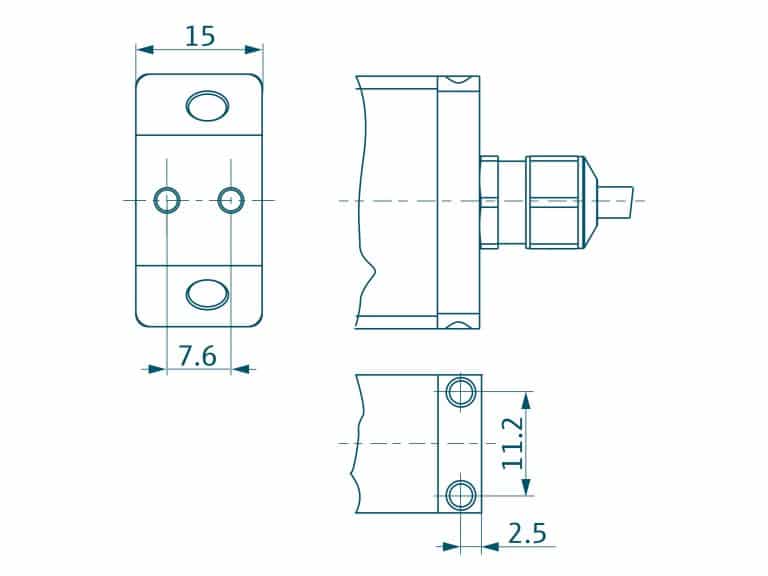

Thanks to measurement in the MEMS system, the sensor is only 37 x 83 x 18.2 mm³ in size and can be accommodated even in tight spaces. The high-precision measurement results are immediately available, allowing continuous measurement during the process. The density of liquids depends on their temperature. To compensate for this effect, an integrated platinum resistor detects the temperature of the liquid.

The density sensor sends the measured data to the readout system via the data line in Modbus RTU transmission mode.

Technology

Overview

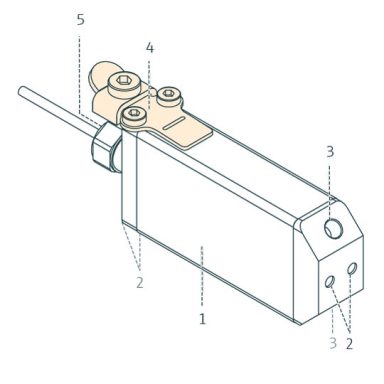

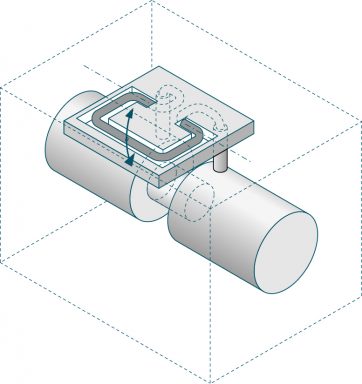

The density sensor was designed for measuring the density of fluids. This takes place using a microelectromechanical system (MEMS) with a microchannel shaped liked the Greek letter omega (omega chip), which is built into an internal bypass.

When the medium flows through the density sensor, the bypass arrangement generates a pressure gradient via the microchannel, which allows the medium to reach the omega chip. The medium influences the physical properties of the excited sensor (resonance frequency and quality), and these are digitized and evaluated in the microcontroller. The measured values can be read out via the serial interface (RS-485, Modbus).

Density measurements in the range 600 to 1000 kg/m3 (further options see product specifications) can be realized at a flow rate of 0 to 10 l/h.

Omega Chip

The Omega chip, a vibronic microsystem, is the heart of the measurement system and serves to generate the sensor signal in the overall system. The essential component of this microsystem is a silicon tube (microchannel) which is vibrated electrostatically in a vacuum. To compensate for temperature effects, a platinum resistor is integrated, which allows local real-time temperature detection. The Omega chip consists essentially of crystalline silicon and glass.

Measuring principle (omega chip)

Density Measurement

For density measurement, the density sensor uses the omega chip. The filled microchannel is set into resonant oscillation and analysed. The resulting natural frequency of the microchannel depends on the mass and thus on the density of the medium in the microchannel: the greater the medium density, the lower the natural frequency. The natural frequency is thus a function of the density of the medium.

![]()

f = natural frequency, E ⋅ I = tube stiffness, ρTube = tube density, ATube = tube cross-section, ρFluid = fluid density, AFluid = fluid cross-section.

|

|

|

- DLO-M2_ex sensor measures liquid density in hazardous areas (ATEX: II1G, IECEx: Zone 0).

- Utilizes MEMS technology with an omega-shaped microchannel for density measurement.

- Compact design, measuring only 37 x 83 x 18.2 mm³, suitable for tight spaces.

- Integrated platinum resistor compensates for temperature effects.

- Sends data via Modbus RTU in RS-485 point-to-point connection mode.

- Ideal for inline measurement, providing instant results and easy media change.

- Offers high precision with a max measurement error of ±0.5 kg/m³ and repeatability of ±0.25 kg/m³.

- Suitable for various fluids including hydrocarbons, aqueous media, and more.

- Optional concentration packages for different liquids such as sugar/water and ethanol/water.

- Applications include airfield refueling for precise mass calculation and concentration monitoring in refrigeration circuits.

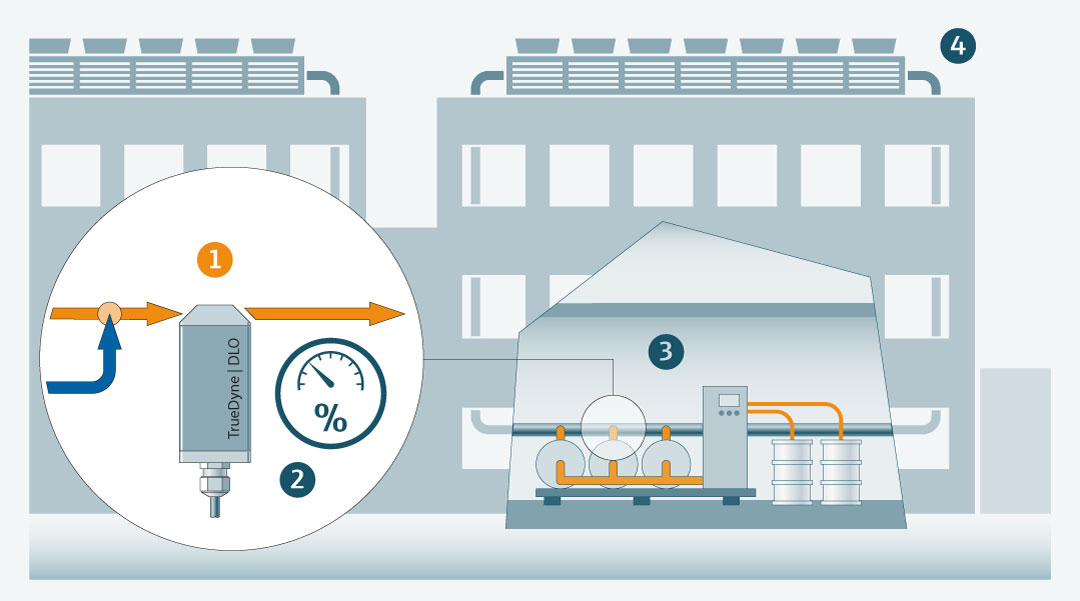

Airfield Refuelling

When kerosene is pumped from the airfield distribution system into an aircraft by a pump truck, the volume of fuel is recorded as standard. However, since the density varies according to pressure and temperature, it is not possible to make precise statements about the mass. For this reason, samples are taken from the tank farm throughout the day and handed over to the pilot for calculation of the mass. With the DLO-M2_ex sensor from TrueDyne, you can collect the necessary data on the density during the process and use them to calculate the mass (V-ρ=m).

1. Standardised volumetric measurement in litres.

2. Installed in a bypass line, the density sensor DLO-M2_ex measures the density directly on the pump truck. Thanks to the compact design of the sensor, it can also be retrofitted into the process.

3. The kerosene is pumped from the airfield distribution system into the aircraft.

Together with the volumetric measurement, the density can be used to calculate the mass of the fuel in kilograms, which is then handed over to the customer. In addition, the density provides important information about the quality of the fuel, which is another safety feature in flight operations.

Concentration monitoring

The refrigerant in a refrigeration circuit is in most cases a mixture of ethylene glycol and water. The optimum concentration is determined depending on the minimum temperature entering the circuit in order to prevent the liquid from freezing. At the same time, the aim is to keep the water content as high as possible, as this has a positive effect on thermal conductivity. So how can the concentration of the glycol-water mixture in the process be monitored? With TrueDyne’s DLO-M2_ex sensor, you collect the necessary data to determine the concentration of the medium in the running process.

1. Density sensor with integrated glycol-water concentration calculation.

2. Concentration is directly output as measured value.

3. Refrigeration system and concentration processing for cooling industrial applications.

4. Heat exchanger on the roof of factory buildings. Due to the circulation water can evaporate and the concentration of the refrigerant changes. Here the DLO-M2_ex is used for concentration monitoring.